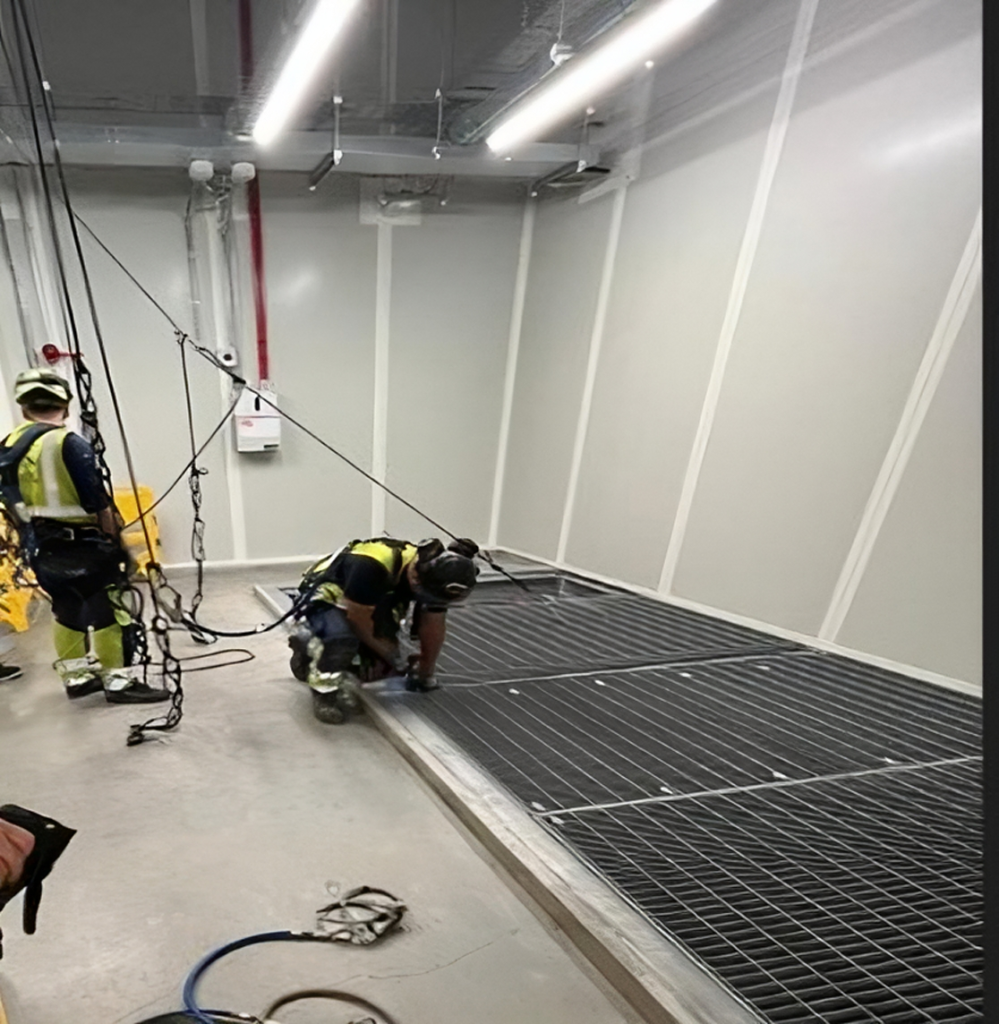

Depending on how many technicians we were using during each shift working in the area, steps 6-7 were repeated until enough ropes are rigged to satisfy the number of technicians.

Where the ropes encounter the leading edge or any other friction points, both ropes and assets were protected with a combination of DMM pads and wire bonds.

Buddy check” took place prior to any abseiling work. This included an inspection of all rigging and anchor points.

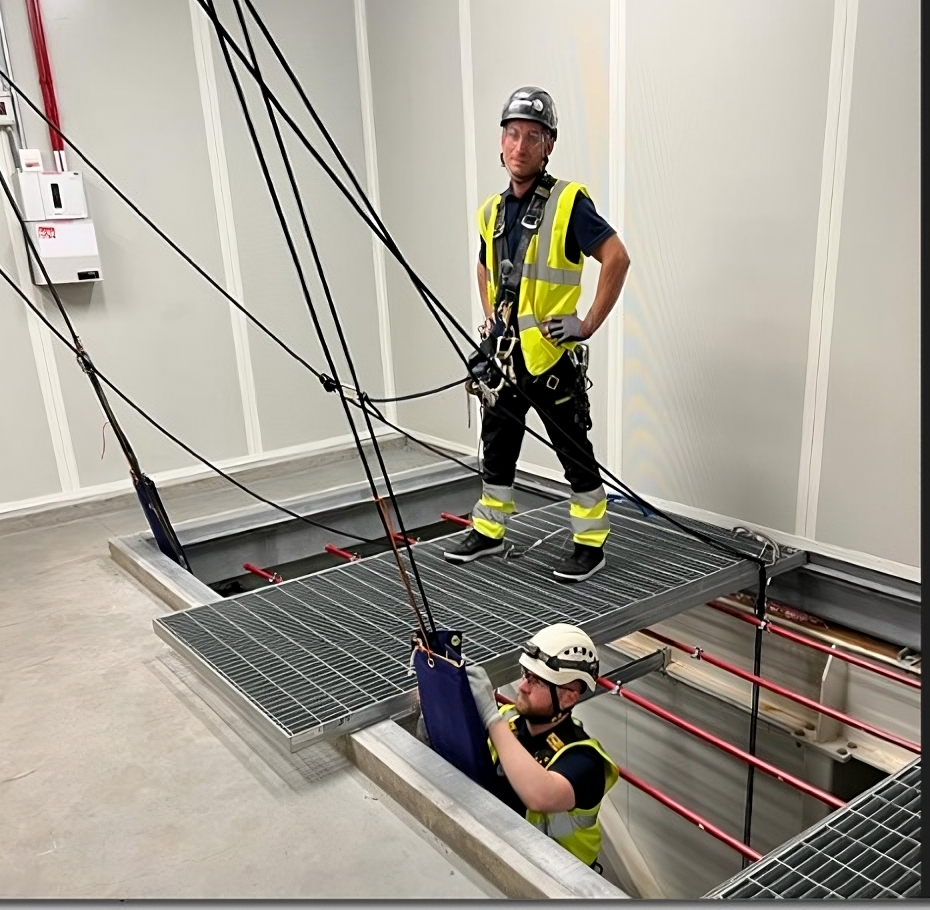

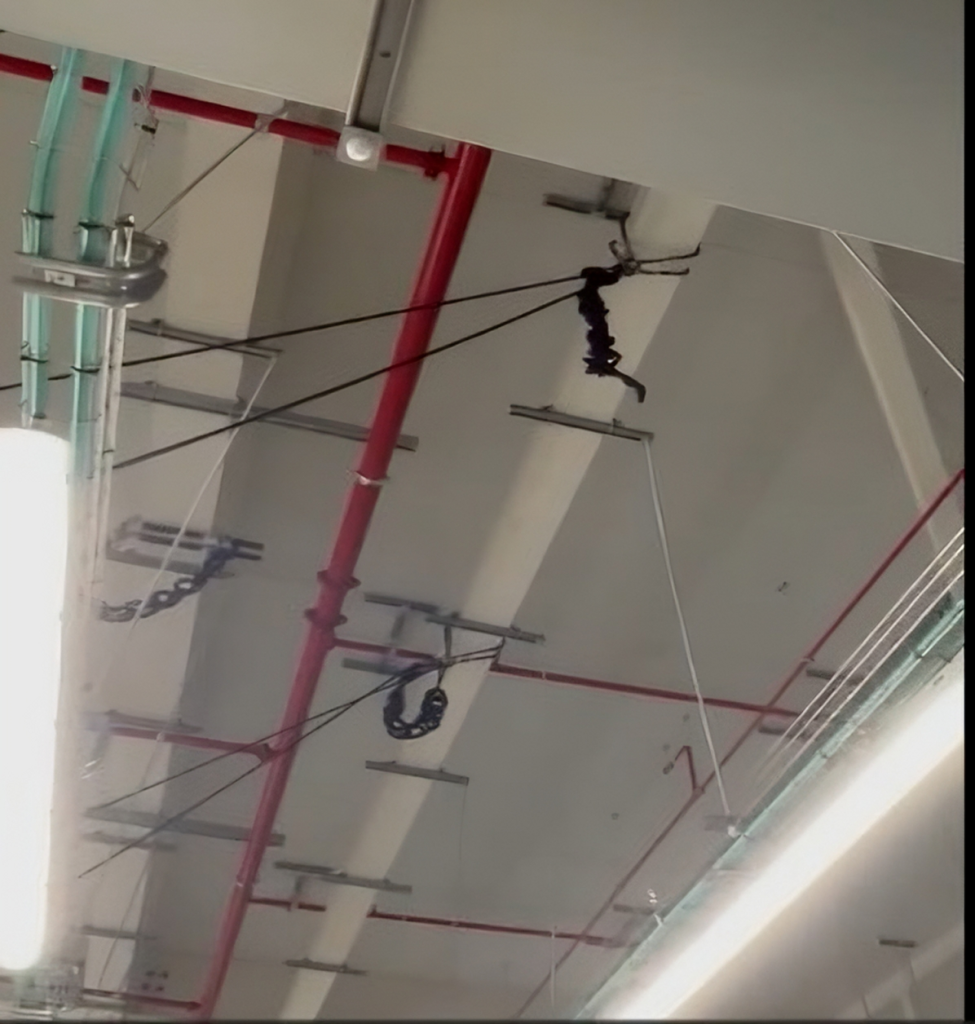

Our rope access expertise was necessary to access the void spaces between floors situated beneath floor grated walkways in a safe, controlled method above suspended ceilings.

IRATA Level 3 supervisor inspected and approved all the anchor points prior to rigging the system of work.

Firstly, a twin ropes tension line will be rigged between two of the main steel structural supports. This allowed for the technician to be in fall restraint whilst they connected to their working lines.

Secondly, using an operated MEWP, the technician initially secured 2 NO. Beam clamps (as per the manufactured recommendations) to the overhead steel work above the first void opening to be cleaned.

Each pair of beam clamps will have a pair of semi static kernmantle ropes connected to them using a figure of 9 knot with a karabiner. This is one working line and one backup line. This is sufficient for one user and tools.

All tools and equipment being used during the process of the works were tethered to the technician. The weight of these items did not exceed 8kg. If so, an additional safety/ hauling and lowering line was made available to the technician.

Firstly, the team used backpack hoovers to remove as much dust as possible. They work from the top down being mindful of the ceiling tiles below.

Once as much dust as possible has been removed we start using the cloths.

Using damp micro cloths, the technicians systematically wipe all surfaces meticulously within the void.

Finally dry micro cloths were used.

Each area was signed off by the client representative and the area cleaned was sealed to prevent contamination and airborne matter entering the void space.